Today, people are especially interested in the design of the kitchen and the tools and utensils they buy. They are increasingly aware of problems linked to the environment and try to make more conscious choices.

Today, people are especially interested in the design of the kitchen and the tools and utensils they buy. They are increasingly aware of problems linked to the environment and try to make more conscious choices.

However, they are not willing to renounce elegance, aesthetics, and functionality. Custom cutting boards and knife handles can be real objects of design, giving a precious look to the kitchen.

In this article, we discuss the most important aspects to evaluate when you plan to widen your kitchenware tools catalogue.

Why should you offer custom cutting boards in your catalogue?

Beautiful and custom cutting boards, personalized according to your clients’ requests and standards, can make the difference and let you stand out in the market.

These are the topics we will cover in this article. You can click the link to read the corresponding paragraph:

- Wood vs. plastic cutting boards

- Wooden cutting boards

- The wood grains

- Plastic cutting boards

- How to be more “green”

Wood vs. plastic cutting boards: the differences

When discussing kitchenware utensils, the first objects that come to mind are knives. Most brands and companies think they are the most important tools to consider, and they try to offer the best and most resistant knife handles and blades.

Even if kitchen knives are essential to have, however, cutting boards are also necessary. Cutting boards are not all equal, and they can directly affect the cooking experience as well as the design of the kitchen.

First, let’s consider the best material to choose.

First, let’s consider the best material to choose.

Cutting boards can be made of different materials, but wood and plastic are the most common options.

Here’s an overview of the advantages and disadvantages of the different materials for custom cutting boards. This will allow you to make an informed decision about the best ones to offer in your catalogue.

Wooden cutting boards

Two groups of wood can be used for cutting boards: hardwood and softwood.

- Hardwoods—e.g., oak, cherry, teak, European beech, and maple—are more resistant and generally offer a superior level of strength and durability. They don’t scar as easily as softwoods and plastics.

- Softwoods—e.g., cedar, pine, redwood, spruce, and yew—are flexible, lighter in weight, and less dense than most hardwoods. They are less strong than hardwood, but they won’t dull your knife as quickly as other woods.

Harwoods are most commonly used to create prestigious, elegant, and durable cutting boards. They are less likely to end up with grooves from knives where bacteria can grow, making them safer.

Moreover, even if a wooden cutting board gets cuts, it doesn’t have to be thrown away. You can easily sand the surface and then rub with some oil to make it look new again.

Wooden cutting boards are also easy on knife blades, so they do not damage them.

There are three types of wooden cutting boards, differentiated by the grain. Each grain has its own unique features, and it’s up to the customer to determine which ones they like.

What are the wood grains?

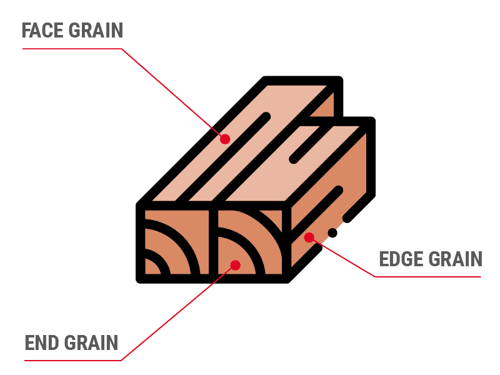

The word “grain” refers to the orientation of fibers in wood or the resulting pattern.

The direction and placement of the grain will affect the aesthetics as well as the durability of the cutting board.

Any piece of lumber that manufacturers use has three surfaces, as you can see in the picture below.

- Face grain cutting boards are made by gluing together the edges of narrow boards of wood. They are ideal for daily use and less expensive, but they are more prone to warping under heavy use.

They are often appreciated, as they bring out the characteristics, nodes, and veins of the wood essence.

- End grain boards are made by cutting a piece of lumber into blocks and gluing the blocks together with the end grain up, forming the top surface of the cutting board. They typically look like a grouping of squares.Cutting boards made with end grains are very characteristic as well as strong and durable. They absorb impact better than the other types and are more resistant.

They are often considered the premium option for custom cutting boards, and they can last for years if properly maintained.

- Edge grain boards are made by gluing together several pieces of wood with the edge facing up, forming a pattern that resembles a hardwood floor. They are a compromise between face grain and end grain both in terms of cost and durability.

They are often used as a utility surface and are ideal for food preparation.

Your customers must be able to choose the best option for them, which is why you should include all these types in your catalogue.

Wooden cutting boards are elegant and prestigious objects that people love to display in their homes. Besides being completely sustainable, they have a strong connection with the past, as all grandmas surely had some in their kitchens.

A competent manufacturer will also be able to customize them with the most innovative finishes, laser engravings, and special coatings according to your and your clients’ requests.

Combining the traditional soul of wood with the most cutting-edge finishing options will result in a unique and inimitable product.

Plastic cutting boards

Plastic cutting boards are very common in people’s homes.However, besides being ugly and of little value, they are also less hygienic.

People may think they are easier to sanitize since they can be put in the dishwasher unlike wood, but every time you leave a cut on the plastic surface, it becomes a perfect place for bacteria. The more scarred plastic boards get, the more difficult they are to clean.

Unlike wood boards, plastic doesn’t have “self-healing” properties, so bacteria can hide and survive even after being washed.

According to the FDA (Food and Drug Association) Food Code:

Cutting surfaces such as cutting boards and blocks that become scratched and scored may be difficult to clean and sanitize. As a result, pathogenic microorganisms transmissible through food may build up or accumulate. These microorganisms may be transferred to foods that are prepared on such surfaces.

Plastic boards are less expensive than wooden ones, but they must often be replaced to ensure safety and hygiene.

Consumers want to be more “green”: how to satisfy them

Kitchenware design can positively or negatively affect the environment. Consumers today are aware that their everyday actions can have a significant effect on safeguarding the planet, and they try to make more conscious choices in all aspects of their lives.

They increasingly prefer eco-friendly objects and tools for their homes to reduce plastic usage and lower their carbon footprint.

However, they don’t want to give up elegance and prestige. They look for beautiful and unique objects, customized according to their preferences and needs, in line with their houses’ style.

Therefore, brands and companies strive to find producers that can satisfy these demands.

Offering sustainable, distinctive, and top-quality wooden cutting boards and knife handles in your catalogue can let you gain a competitive edge in today’s market.

To be sure about that, you must select a reliable manufacturer. Sustainability, in fact, is not just about the raw materials. Wood is eco-friendly by its nature, but it doesn’t mean it is completely sustainable.

To be sure about that, you must select a reliable manufacturer. Sustainability, in fact, is not just about the raw materials. Wood is eco-friendly by its nature, but it doesn’t mean it is completely sustainable.

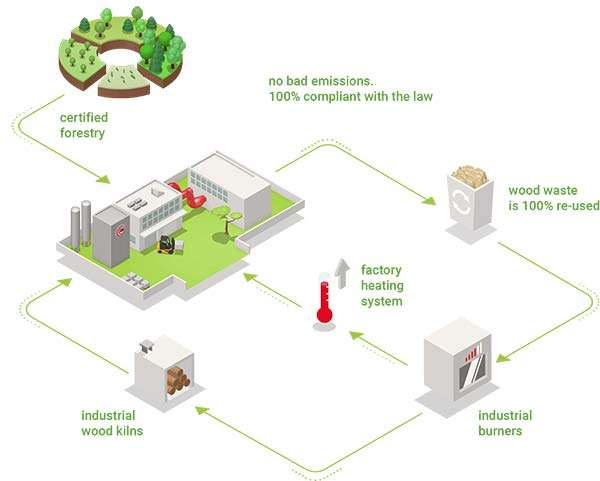

You must consider the entire production process, from collection of the raw materials to manufacturing and distribution:

Raw materials must come from responsibly managed forests to ensure that for every tree harvested another one replaces it. There is a significant difference between deforestation and sustainable logging, which means cutting trees and always caring about wildlife, biodiversity, regeneration, and forest health.

Forest Stewardship Council® certification (FSC International) guarantees that the raw material comes from responsibly managed forests.

Sustainable manufacturing means that your partner must pay attention to energy and the proper use of resources. A company that produces wood products produces a large amount of scraps every day. Discarded materials can be used to produce smaller objects or fuel heating systems.

Moreover, a sustainable company should adopt energy-efficient systems and technologies and periodically conduct an energy audit.

Regarding distribution, transportation logistics and vehicle emissions represent a risk for the environment. It would be especially important that the manufacturer has production plants where raw material is collected in order to reduce the carbon footprint.

Look at this video to understand what we mean by a sustainable production process:

Becoming more “green” means knowing where objects come from, how they are produced, how long they will last, and where they will end up once thrown away.

Traceability, reuse, and recycle are key points of the circular economy model.

Our approach integrates an environmentally friendly vision with the design of unique and distinctive objects, customized according to clients’ needs. Thanks to our deep experience in wood manufacturing combined with the use of the latest technologies and cutting-edge machines, we can ensure the highest quality standards.

Our company has always focused on sustainability: in 1999, we were among the first to be certified by the FSC when it was not a standard yet.

We recently underwent an EcoVadis Audit and received a highly positive rating in terms of environmental, labor & human rights, ethics, and sustainable procurement impact.

This demonstrates our sincere dedication to pursue a responsible manufacturing model that respects the environment as well as all ethical aspects of business.

If you are looking for custom cutting boards, wooden knife handles, or any sort of kitchenware tool, do not hesitate to contact us!