Since the green trend is spreading and consumers are becoming more and more aware of environmental issues, you have decided to include wooden products in your catalogue. It is surely a good idea, considering that sustainability is a topic that influences buyers today. The question is: how to find the right supplier? Let’s discuss it in this article.

Since the green trend is spreading and consumers are becoming more and more aware of environmental issues, you have decided to include wooden products in your catalogue. It is surely a good idea, considering that sustainability is a topic that influences buyers today. The question is: how to find the right supplier? Let’s discuss it in this article.

Choosing the custom wood products supplier: which are the things to evaluate?

When you decide to offer custom wood products to your clients, choosing the best supplier requires careful evaluation of various aspects.

In this article we will see:

- Some considerations about the ideal custom wood products manufacturer

- The essential characteristics your wood products supplier must have

Some considerations about the ideal custom wood products manufacturer

When we talk about wooden objects, there are some fundamental aspects you have to look attentively at. Wood, in fact, is not easy to process: the manufacturer you select must have specific knowledge and expertise and must be able to create a successful partnership to achieve perfect results. Here are some points to take into consideration.

Knowledge of wood—Wood is not easy to process because it changes constantly, being a natural material. It means that the wood maker must have a deep knowledge of the different types of wood and their specific characteristics. Each wood type, in fact, has its precise tolerances and needs the right machinery to be managed. To guarantee precision and quality, great expertise and innovative tools are fundamental.

Co-design—Slight modifications to the design of components may affect the production process and product functionality. A qualified wood maker with deep experience in a wide range of industries and applications can provide codesign services to help its clients optimize product specifications even before production.

Co-design—Slight modifications to the design of components may affect the production process and product functionality. A qualified wood maker with deep experience in a wide range of industries and applications can provide codesign services to help its clients optimize product specifications even before production.

Precision & quality consistency—Wooden components are generally designed to be assembled with other materials, so you need to be sure about the perfect fit. For example, in the world of cosmetic or spirits packaging, caps must fit perfectly on the bottles to avoid contamination or product leakage. In other cases (such as hand tools or gun stocks), wooden parts should accommodate metal or plastic components. A lack of precision results in additional processing or production waste. The ideal wood maker should also be able to guarantee maximum precision and quality consistency for large lots of production parts. Unique & innovative finishing—Wood can be enhanced with many innovative and glamourous finishes, but not all wood makers have the right technologies to do that. Only a highly specialized supplier who produces only wooden objects can offer a wide array of the most modern finishes.

Unique & innovative finishing—Wood can be enhanced with many innovative and glamourous finishes, but not all wood makers have the right technologies to do that. Only a highly specialized supplier who produces only wooden objects can offer a wide array of the most modern finishes.

Cost-effective—Wood is expensive, so you have to be sure to find a wood maker who can guarantee cost-effectiveness. It means that he must provide high-quality products delivered on time at a competitive price. This requires a deep knowledge of wood processing to optimize production and develop the most effective flow, from ordering raw materials to delivery.

Eco-friendly certifications and social responsibility—Sustainability is a subject particularly dear to modern consumers because they are more and more aware of the problems of the planet and the ecosystem today due to a lack of regulations and attention by most companies. Wood is sustainable, but it has to be collected following strict guidelines for environmental and forestry protection to preserve the natural ecosystem. FSC certification demonstrates it, but not all suppliers adhere to the necessary requirements. Innovative firms can’t ignore the social context in which they operate and must consider more ethical values that go beyond profit. If the company purpose is not the sole pursuit of profits, it positively influences the work of employees too.

Considering the importance of the supplier at every stage of the product life cycle, it is not a decision to be taken lightly. Given the points above, what do you have to consider when choosing your custom wood products supplier? What characteristics must you look for and the details that make the difference?

Considering the importance of the supplier at every stage of the product life cycle, it is not a decision to be taken lightly. Given the points above, what do you have to consider when choosing your custom wood products supplier? What characteristics must you look for and the details that make the difference?

Let’s discuss them.

The essential characteristics your wood products supplier must have

Innovation & reliability

A serious and competent wood maker guarantees clients’ deadlines and delivers each order as scheduled. But how can you know that in advance? To determine if the supplier can be reliable, look at the company structure and reputation.

First, you have to ensure that the custom wood products supplier has modern and innovative machinery, a consolidated process, and tailor-made logistic solutions. If the company has a decennial heritage, its competencies have been demonstrated over the years and are recognized even by its main competitors, it means that it’s trustworthy and solid (economically too).

Also having a multiproduct and multi-industry business model is a great advantage. If the company operates in different fields and industries (it produces very different types of custom wood products), it can benefit from cross-fertilization among them. It means that innovations and technologies applied in one industry can be moved and exploited in another one, with continuous development of abilities, knowledge, and expertise.

Also having a multiproduct and multi-industry business model is a great advantage. If the company operates in different fields and industries (it produces very different types of custom wood products), it can benefit from cross-fertilization among them. It means that innovations and technologies applied in one industry can be moved and exploited in another one, with continuous development of abilities, knowledge, and expertise.

Then you have to consider that, if the supplier is recognized as an expert in the field, he has probably collaborated with prestigious and famous brands. This can truly demonstrate and certify his professionalism and quality of work.

Focus on industry 4.0

Producing one hundred perfect components is easy. Producing one million requires special skills, and your selected supplier must be able to create one million high-quality, precise pieces. Many companies are not able to do that. You need to ensure that the producer follows strict manufacturing procedures and uses ground-breaking technologies to guarantee precision for each production lot.

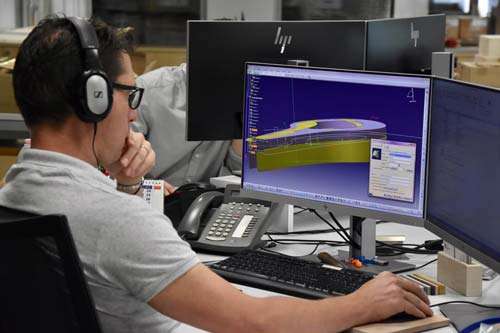

Your ideal partner must have a strong focus on Industry 4.0 and Information Technology. What does this mean? It means that the supplier has a culture of continuous innovation, and he invests a lot to get the newest machinery and systems; he wants to make his company a smart factory based on automation, interconnectivity, machine learning, and real-time data, exploiting the power of Industry 4.0. It must be said that younger employees’ energy can boost this process. If the average age of workers is young, the company has invested in human resources and believes in the power of new ideas.

Your ideal partner must have a strong focus on Industry 4.0 and Information Technology. What does this mean? It means that the supplier has a culture of continuous innovation, and he invests a lot to get the newest machinery and systems; he wants to make his company a smart factory based on automation, interconnectivity, machine learning, and real-time data, exploiting the power of Industry 4.0. It must be said that younger employees’ energy can boost this process. If the average age of workers is young, the company has invested in human resources and believes in the power of new ideas.

All these aspects make the company more flexible during production and design phases, guaranteeing a fluid and adaptive organization even in such a complex environment. The evidence is manual quality control. If the custom wood products maker can show you that besides automation and sophisticated software there is also human control over production, the possibility of obtaining precision and consistency is greater. Constant care is not an option.

Risk management

Constant care also means the capacity of individuate, anticipate and possibly manage risky situations. The ideal manufacturing company is multi-plant: it means that if some major damage occurs in one of the plants, the supplier is able to quickly switch production to another plant. In this way, the process becomes smarter and can continue without any negative consequences for clients.

Processes & cost optimization

Products must be cost-effective: the supplier must guarantee quality, but you have to pay the right price for that. The positive aspect in working with wood is that it doesn’t require moulds, which are expensive not just in terms of money but also of time:

- First, whenever the mould you’ve created has to be modified, it requires additional investments in time and money, and you won’t always be able to bring it precisely to the desired form. Wood, on the other hand, can be modified, reshaped, and enhanced each time depending on clients’ requirements.

- Second, after many processes of refinement and finishing, wood can resemble plastic. The advantage is that if you use a cheap type of wood the investment will be lower, and you can expand the range of products.

The plus occurs when the supplier can produce goods in small lots and only when clients request them without needing a warehouse. It means a greater focus on efficiency and remarkable savings. Moreover, the possibility to produce half-processed products and then complete production depending on the market trend and consumers’ preferences is important because you can adapt production to the market with a better chance of success.

The plus occurs when the supplier can produce goods in small lots and only when clients request them without needing a warehouse. It means a greater focus on efficiency and remarkable savings. Moreover, the possibility to produce half-processed products and then complete production depending on the market trend and consumers’ preferences is important because you can adapt production to the market with a better chance of success.

Being able to guarantee “just in time” delivery is also fundamental. Some suppliers can provide customizable private stocking solutions, manufacture products in advance, and store them in secure and safe warehouses. In this way, clients can order their components from stock with virtually instantaneous delivery. If one of these elements is absent, it is impossible for the supplier to guarantee perfect and impeccable service.

Empathy & cooperation

Finally, the human aspect is important. To get a wooden product that responds to your needs and standards, you have to find an emphatic and responsive wood maker who is ready to cooperate with you and help improve the different aspects of the final object. This means that during the design phase the supplier must be able to provide consulting services before moving on to production.

Being able to model and simulate the final product and providing a sample or prototype is surely a plus. If you can see and touch the final product, you will be able to evaluate it and decide if it corresponds to your requirements and needs.

Being able to model and simulate the final product and providing a sample or prototype is surely a plus. If you can see and touch the final product, you will be able to evaluate it and decide if it corresponds to your requirements and needs.

Finding a supplier which corresponds to all these requirements is not always an easy task. However, if you look at manufacturers with several decades of experience in different industries (like Minelli S.p.A) you’re more likely to identify the right partner. Since 1937, Minelli S.p.A. has ensured perfection in the quality and design of each product manufactured, and its experienced specialists serve customers in the best way possible, following rigorous processes and environmental sustainability.

If you have a project in mind, don’t hesitate to contact us! Our experts will be glad to evaluate your plan and help shape your idea. Click here!