Very long delays in production and distribution of raw materials, components, and products are one of the worst problems that are affecting today’s global markets, including that of electric guitar bodies and necks. Clients must wait months to receive their goods, which causes serious issues for their business.

Very long delays in production and distribution of raw materials, components, and products are one of the worst problems that are affecting today’s global markets, including that of electric guitar bodies and necks. Clients must wait months to receive their goods, which causes serious issues for their business.

In this article, we give you some advice to ensure your custom guitars arrive on time. Keep on reading!

Electric guitar body market: how to deal with the CURRENT situation

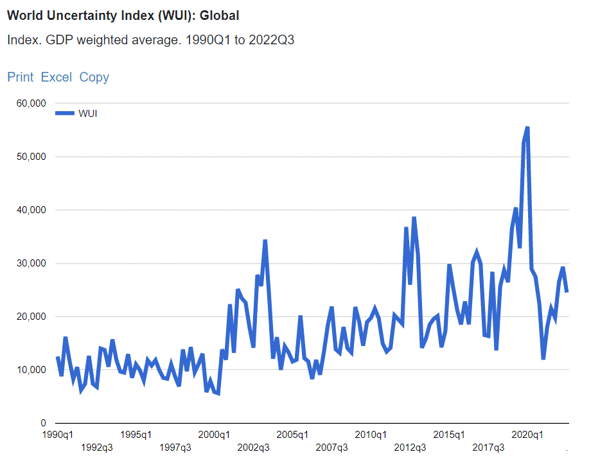

Uncertainty characterizes today’s global market.

The World Uncertainty Index—a quarterly measure of global economic and policy uncertainty covering 143 countries—shows that although uncertainty has come down by about 60 percent from the peak observed at the onset of the COVID-19 pandemic in the first quarter of 2020, it remains about 50 percent above its historical average from 1996 to 2010.

Source: https://worlduncertaintyindex.com/

Source: https://worlduncertaintyindex.com/

One of the most evident aspects is that companies order products, components, and raw materials from their suppliers, but they can’t know when they will receive them, especially if they rely on China. Consequently, consumers, too, can’t know when they will get the products they order.

Due to the pandemic emergency, Asian major ports closed, which limited the arrival of goods in such markets as North America and Europe. Then, Russia’s invasion of Ukraine made delays even worse, as more than a million containers that were sent to Europe from China by train through Russia must now be sent by sea, as sanctions are serious (Source: Wired).

Developing appropriate strategies to deal with this situation effectively is crucial to stay ahead of competition and keep business growing.

One way is finding alternative suppliers that can respect deadlines and send products on time.

Finding suppliers of an electric guitar body in your country is the solution

Most American and European brands think they must produce their wooden electric guitars far away from their own countries with no possible alternatives, but this is not true.

On the contrary, choosing a manufacturer located in your own country is a great advantage:

On the contrary, choosing a manufacturer located in your own country is a great advantage:

- you can avoid uncertainty and delays that could affect your commercial activities

- you don’t have to deal with distance, which can be a major problem for communication, especially during the design phase when you need to cooperate closely with your partner, and it should help you materialize your ideas

- you can see and touch a physical prototype of the electric guitar body and neck to understand if they correspond to your project or if some modifications are necessary

- you can talk with experts and understand more about the production process they implement to create your products to ensure they use cutting-edge, innovative machinery and tools to make top-quality electric guitars

- you can have private stocking of the components you order, which allows you to order specific quantities just in time according to your actual demand while customizing the type of finish

If the manufacturing company is flexible and can produce wooden components in small lots and only when clients place an order, you have a great advantage to reduce possible risks.

Consider if it can set-up production lines specific for electric guitars.

Some suppliers can also provide customizable private stocking solutions, manufacture products in advance, and store them in secure and safe warehouses. In this way, clients can order their components from stock with virtually instantaneous delivery thus reducing lead time.

Technology, too, has a crucial role to overcome this situation

Wood manufacturing companies that continue to invest in new technologies and machinery even in this difficult situation are those that can handle it better.

Interconnectivity, innovative software and tools, and automation are essential to optimize everyday operations and make them faster while avoiding mistakes to guarantee deadlines are respected without unnecessary added costs.

Also, the capacity of individuate, anticipate and possibly manage risky situations is fundamental. The best supplier is multi-plant. If a problem occurs at one of the plants, it can switch production to another plant to ensure continuity of production without any negative consequences for clients.

An expert supplier should adapt quickly to changes in trade flow, new regulations, the impact of COVID-19, climate change, trade tensions, and other geopolitical issues without negatively affecting client business.

Since 1937, Minelli S.p.A. has ensured perfection in the quality and design of each product manufactured by relying on the experience of our employees, the most innovative tools, and consolidated wood manufacturing processes.

We use only the latest generation of customized and made-for-purpose CNC machines that provide consistent dimensional and finishing results even at a very high production volume.

Many of our machines are unique and custom made.

We have production plants in both Europe and the U.S., and we can provide customizable private stocking solutions to guarantee just in time delivery.

Moreover, our internal R&D department constantly observes the market to develop innovative finishing options according to market trends and customers’ preferences.

If you are looking for a custom electric guitar body or neck or have a project in mind, contact us now!