Around the world, supply chain problems are affecting the supply of goods, as easing of the Covid pandemic has led to a sudden and unexpected surge in consumer demand.

Around the world, supply chain problems are affecting the supply of goods, as easing of the Covid pandemic has led to a sudden and unexpected surge in consumer demand.

Today, most American and European brands think they must produce a wooden electric guitar body and its neck far away from their own countries, with no possible alternatives, but this is not true.

Producing in your own country is not only possible but also a great advantage in terms of quality, possibility of customization, productivity, risks & delays prevention, and competitiveness.

We discuss this topic in the following article.

Electric guitar body and neck production: why choosing an American or a European manufacturer is the right choice

Especially today with the supply chain crisis affecting many countries across the world, choosing a wooden guitar supplier located in another continent can be a great risk.

If your company is in the U.S. or Europe, choosing a manufacturer that has production plants in your own country has many advantages both in terms of shortening lead time and convenience.

Here are the topics we will deal with in this article. You can click the link to read the corresponding paragraph:

- The supply chain crisis

- Why wood manufacturing is complicated

- The importance of codesign

- Creating a customized electric guitar body

- Advantages of flexible production

- Reduction of lead time and competitiveness

The supply chain crisis

Empty shelves, rising prices, and long delays. The supply chain crisis that is affecting many countries around the world today has occurred because demand after the pandemic has rebounded much faster than expected and much faster than the world economy is able to supply the goods required.

The complex network of factories, ports, container ships, trucks, and rail lines has been unable to keep up with this rapid rebound, leading to chaos in the global supply chain, from food and drink to clothing, books, electronics, and toys.

In the U.S., container ships—mostly from Asia—must wait to dock sometimes for as long as three weeks, as ports are congested, resulting in serious delays and shortages of goods. According to The Wall Street Journal, the price per container has risen to as much as 10 times its cost before the pandemic.

Therefore, those companies that relied especially on China for most finished products and components are now suffering debilitating supply chain shortages.

The situation is explained in detail in this video from WION:

It is clear that relying on a manufacturer located in your own country—whether in Europe or the U.S.—is safer and more convenient.

Why wooden guitar manufacturing is complicated

Creating a top-quality wooden guitar is not easy, especially if you want to customize it according to your client’s requirements. You should know that managing wood is quite complicated, and you need specific and innovative technologies and software to create perfect products.

Nature, in fact, has hundreds of wood essences, each with its own characteristics, standards, and structural limits that a competent supplier must know and respect to treat properly.

Wood manufacturing is not like managing plastic. Wood is a natural material that moves constantly and has specific tolerances, i.e., specific dimensional data properly calculated during project development, considering the natural variations of the material, that can have a significant effect on the precision and functionality of the final product.

Wood must be prepared carefully to receive the selected finishes and ensure durability and top performance.

Wood must be prepared carefully to receive the selected finishes and ensure durability and top performance.

For example, the correct moisture level of the raw material is necessary to ensure a clean milling process, higher dimensional stability, less risk of breakage, and higher productivity at lower cost.

If wood has a high percentage of humidity, shape and volume may warp over time. A U.S. or European manufacturer that operates exclusively in the timber sector will have special drying chambers that ensure the correct degree of exsiccation before moving to production.

Managing the drying process internally rather than outsourcing brings a specific advantage in quality and longevity of the final product.

Moreover, woods used to build guitars are very particular. They are known as tonewoods, as they have a particular tone and are used to achieve a certain sound. Different woods will give the guitar different sound qualities, and they must be carefully and properly machined to obtain the desired effect.

Only a multinational company that knows the raw material very well and invests a lot of time and money into the latest machinery and tools can create premium custom-made electric guitar body styles.

The importance of codesign

The design phase is essential in each project. It is part of the process when you talk with your partner, and it helps you in developing and giving shape to your ideas. If you have any problem, your supplier must be ready to cooperate and give advice.

Distance can be a problem in this sense. If your supplier is halfway around the world, it can be hard to coordinate with the time difference, resulting in communication difficulties and possible delays.

Your supplier should be your point of reference and at your disposal whenever necessary. Especially during the design phase, you and your partner should work together to determine the feasibility of your project as well as possible problems and issues and how to solve them.

An expert manufacturer will be able to provide physical samples of the final product so that you can evaluate it and decide if it corresponds to your requirements, making modifications if necessary. This ensures optimal quality, performance, and cost.

If the prototype is just a 3D simulation of the final product and does not perfectly represent it, your clients won’t have a precise idea of the technical and functional performance of their guitar before production.

This can result in unexpected costs and unforeseen problems during the production phase.

Creating a customized electric guitar body and its neck

A guitar is not just an object: it can be a collector’s item that people love to show to others. Moreover, it must be functional, comfortable to use, good to play, and adapt to the owner’s physical and aesthetical requirements.

To respond to all these needs, the manufacturer must be able to simulate even the most difficult drawing without disturbing the concept and the general feeling of the original design.

This could mean creating complicated shapes, doing something that nobody has done before, and finding solutions to meet even the most demanding requirements.

Only an experienced team specialized in the timber sector has the competency and tools to create such difficult designs, maintaining the highest standards of durability, resistance, and functionality.

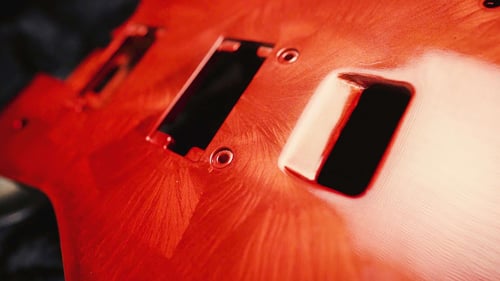

Moreover, you should be able to offer many finishing options to satisfy your clients’ requests. The electric guitar’s appearance is also an element of its utility. For many players, their guitar must not only be functional for the type of music they play but also in line with the specific image they want to convey.

There are two main reasons for applying a finish to a wooden guitar: protection and appearance. The coating applied on the surface protects the body from dust, moisture, impact, and wear, and it also makes wood more elegant, glamourous, and prestigious.

You need advanced technologies to prepare the wooden surface for the final finish in the most precise and durable way. Wood must be carefully sanded with dedicated equipment before applying the coating.

A U.S. or European multinational manufacturing company can rely on decades of strong relationships and collaboration with the world’s leading producers of wood finishing materials, e.g., oils, paints, lacquers, and resins, so that it can offer a wide range of finish options, giving advice about the best to use.

How to face the actual supply chain crisis?

Download the free whitepaper now!

If your supplier has an internal R&D department, you can be sure they can develop new and unique materials and ensure constant improvements.

It is also necessary that your clients can brand the electric guitar body they sell. Laser technology lets them have their logo on the body of the guitar (white label) and also some deco and grip on the wooden surface.

Many companies still use pyrography or hot molding on wood, and the most innovative companies have anthropomorphous laser robots that adapt to each shape with radial movements and different engraving depth. This lets them create even the most complex and technical designs.

Notice also that different from silk-screening or hot stamping, lasering doesn’t need any ink or added chemical, resulting in an eco-friendlier technique.

Advantages of flexible production

Whereas most manufacturers use multipurpose production equipment for the electric guitar manufacturing process, a U.S./European cutting-edge company should have a dedicated production line to fit the specific needs of manufacturing wooden guitars.

Dedicated production lines let manufacturers be more flexible during production.

It means having the possibility to produce wooden guitars in small lots and apply the desired finish on demand.

As a consequence:

- you won’t need an expensive warehouse, as you can produce only when clients place an order

- you will be able to produce semiprocessed products and then complete the finishing process depending on the market trend and clients’ preferences, with more possibility of success

Being able to guarantee just in time delivery is also fundamental. Some suppliers can provide customizable private stocking solutions, manufacture products in advance, and store them in secure and safe warehouses. In this way, clients can order their components from stock with virtually instantaneous delivery.

Reduction of lead time & competitiveness

Finding a supplier that can provide on demand and flexible solutions is crucial, especially in the situation we are facing today.

The problems of global mobility and long shipping and delivery times lead to clients having to wait even six or seven months to receive the objects they ordered, with negative consequences on their business.

Receiving wooden components on time is fundamental for putting them on the market quickly and start selling as planned.

A multiplant company with production plants in both Europe and the U.S. has great advantages in this sense:

- you can be sure you receive your product on time, as scheduled

- if some major damage occurs at one of the plants, it can quickly switch production to another plant without any negative consequences for clients

That is why choosing a supplier in your own country can be an advantage to avoid uncertainty and delays that could affect production as well as commercial activities.

You should also ensure that your supplier has an internal warehouse where the raw material is stored: if the supplier must buy it externally, lead time can become even longer.

The Minelli Group and subsidiary Minelli USA have manufactured wooden components for the OEM market for more than 50 years.

Thanks to our internal research & development department, sophisticated software, and cutting-edge machines, we can produce innovative and inimitable objects customized according to your clients’ preferences and needs.

We have a culture of continuous innovation, and we invest a lot of time and money to get the newest machinery and systems; our company is a real smart factory based on automation, interconnectivity, machine learning, and real-time data.

We take advantage of well-known Italian craftsmanship that we translate to our American production plant, where we can produce the highest-quality wooden components.

If you are looking for a top-quality wooden electric guitar body and neck or have a project in mind, contact us right now!