The evolution of wood product manufacturing technologies stands as a testament to human ingenuity and environmental stewardship. This article highlights how the adoption of advanced technologies enhances precision and efficiency in wood production. Alongside, we explore the industry's commitment to environmental stewardship through sustainable sourcing and recycling efforts, showcasing wood as an eco-friendly alternative to plastic.

The evolution of wood product manufacturing technologies stands as a testament to human ingenuity and environmental stewardship. This article highlights how the adoption of advanced technologies enhances precision and efficiency in wood production. Alongside, we explore the industry's commitment to environmental stewardship through sustainable sourcing and recycling efforts, showcasing wood as an eco-friendly alternative to plastic.

Discover more!

Modern advancements in wood product manufacturing

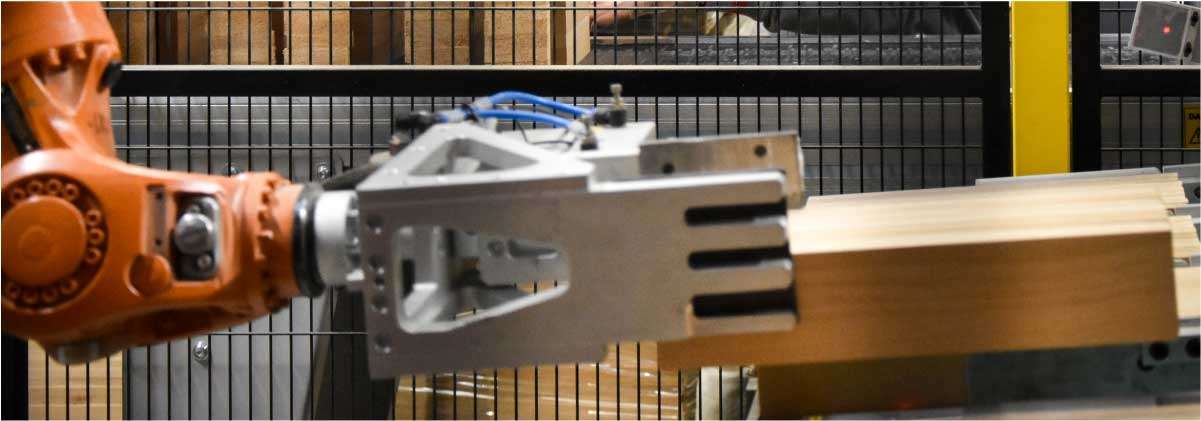

The contemporary wood product manufacturing industry stands at the crossroads of technological innovation and environmental stewardship. At the forefront of this evolution are Computer Numerical Control (CNC) machines, which have revolutionized wood manufacturing processes. These advanced machines provide manufacturers with the capability to execute intricate designs with high precision, ensuring that each piece meets the rigorous quality demands of the modern market. Alongside CNC technology, automated assembly lines further enhance production efficiency, enabling a faster, more reliable output of wood products. This combination of technology ensures that manufacturers can keep pace with the increasing complexity of designs and consumer expectations for quality and craftsmanship.

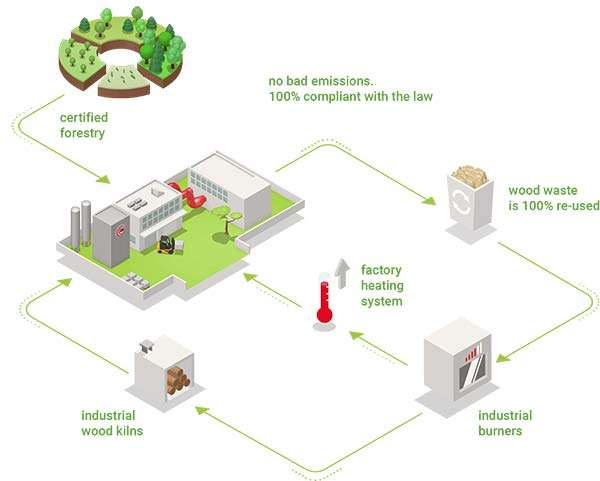

Parallel to technological advancements, the industry has witnessed a significant shift towards sustainability. This shift is driven by a heightened awareness of environmental sustainability and the urgent need to address ecological challenges. Manufacturers have increasingly adopted responsible sourcing practices, prioritizing the use of wood from forests that are managed sustainably. Certification schemes, such as those provided by the Forest Stewardship Council (FSC), are now common, offering assurances that wood products are sourced in an environmentally responsible manner. Furthermore, the industry has made strides in minimizing waste through the recycling of wood materials. By reusing wood waste to create new products or as a source of energy, the industry reduces its environmental footprint and also contributes to a circular economy.

These sustainable practices not only help secure the long-term viability of wood resources but also underscore wood's position as a preferable, eco-friendly alternative to more polluting materials like plastic. The dual focus on harnessing cutting-edge technologies and embedding sustainability into every facet of production underscores the wood product manufacturing industry's commitment to balancing economic growth with environmental preservation. This approach not only aligns with the global push towards sustainability but also enhances the industry's reputation among environmentally conscious consumers, setting a benchmark for responsible manufacturing in the modern era.

Wood vs. Plastic: the environmental and aesthetic superiority of wood

When evaluating materials for both their environmental impact and aesthetic qualities, wood emerges as a superior choice over plastic. This distinction is rooted in several key differences between the two materials.

On an environmental level, wood is a standout for its sustainability and eco-friendliness. It is a renewable resource, capable of being replenished through sustainable forestry practices, unlike plastic, which is derived from non-renewable petroleum resources.

The production and disposal of plastic contribute significantly to environmental pollution and are major sources of global concern due to their long-term persistence in ecosystems and the challenges associated with recycling.

Wood, on the other hand, boasts a naturally lower carbon footprint throughout its lifecycle. Its biodegradability ensures that, at the end of its useful life, wood can break down and return to the earth, minimizing environmental impact. This cycle of growth, usage, and return to the environment underscores wood's role in reducing global warming and pollution, offering a stark contrast to the enduring environmental challenges posed by plastic waste.

Beyond its environmental advantages, wood possesses inherent aesthetic qualities that plastic struggles to emulate. The warmth, natural beauty, and unique characteristics of wood, such as its texture, grain, and color variations, imbue products with a sense of character and elegance that is highly sought after in fields such as interior design and architecture. These natural attributes of wood contribute not only to the visual appeal but also to the tactile experience, offering a connection to the natural world that plastic, with its synthetic nature, cannot match.

.jpg?width=500&height=333&name=18-_DSC5845%20(1).jpg)

Moreover, wood's beneficial properties extend beyond its appearance. When used for furniture or household items, it plays a significant role in creating healthier living environments through its ability to regulate humidity, thus contributing to indoor air quality. Additionally, wood's acoustic properties are valued for their ability to reduce noise levels, enhancing the ambiance of spaces through sound dampening. These functional benefits, combined with its aesthetic appeal, make wood a preferred choice for consumers and professionals alike, further solidifying its superiority over plastic.

The inherent characteristics of wood, coupled with its aesthetic and functional advantages, position it as a material of choice for those seeking sustainability without compromising on quality and beauty.

The evolution of wood product manufacturing technologies reflects a journey of innovation, sustainability, and a rekindled appreciation for natural materials.

However, the choice of supplier is crucial in ensuring that the environmental and aesthetic benefits of wood are fully realized. Opting for suppliers who adhere to sustainable and responsible sourcing practices not only supports the ecological management of forests but also ensures that wood products deliver the superior qualities they are prized for. Therefore, careful selection of suppliers is essential for promoting sustainability, excellence in quality, and environmental integrity in the wood products industry.

The Minelli Group has manufactured wooden components for more than 80 years.

Thanks to our internal research & development department, sophisticated software, and cutting-edge machines, we can produce innovative and inimitable objects, whose quality is recognized all over the world.

In our European and American production plants we can produce the highest-quality wooden components and customize them according to your and your clients’ requirements, with a very brief lead time between development and delivery.

If you have a project in mind, contact us right now!