Questions about how to make manufacturing companies more sustainable and which types of sustainability practices can be more beneficial are still open today. Wood products manufacturers look for ways to stay ahead of the competition and are willing to adopt proactive strategies to satisfy clients’ expectations and enhance their competitiveness.

Questions about how to make manufacturing companies more sustainable and which types of sustainability practices can be more beneficial are still open today. Wood products manufacturers look for ways to stay ahead of the competition and are willing to adopt proactive strategies to satisfy clients’ expectations and enhance their competitiveness.

How do you understand, though, if your manufacturer adopts environmentally-friendly practices? Let’s discuss it in the following article.

Sustainable wood products manufacturers: what does it mean?

Over the last few decades, there has been a growing concern about how manufacturing activities have a negative effect on the environment.

Companies should adopt voluntary environmental responsibility strategies and consider at the same time economic, environmental, and social objectives rather than just apply mere compliance strategies.

Industrial activity, in fact, has contributed to a stable rise in CO2 emissions despite the increasing adoption of environmental policies and standards applied to production processes, and this result is far from the objective of the 2030 Agenda for Sustainable Development and the achievement of the United Nations’ 17 Sustainable Development Goals (SDGs).

The Sustainable Development Goals (SDGs) were approved in September 2015 by the 193 UN member states and are also known as Agenda 2030. The framework consists of 17 goals for environmental sustainability, social inclusion, economic development, peace, justice, good governance, and partnership, which are the main issues for the world population in the 21st century.

Sustainability in manufacturing can be defined as “the creation of manufactured products that use processes that minimize negative environmental impacts, conserve energy and natural resources, are safe for employees, communities, and consumers and are economically sound.” (U.S. Department of Commerce, 2009)

To achieve this goal and promote a sustainable approach in manufacturing, there is the need of a holistic view that includes products and production processes and is applied at every stage of wood manufacturing, from the plant to the firm to the entire supply chain.

According to Transaction Cost Theory (TCT), sustainability practices can be divided into three categories: internal, external monitoring, and external collaborating. (Vachon and Klassen, 2006)

Internal sustainability practices (ISPs) include such aspects as:

- waste reduction

- pollution prevention

- improvement of the workforce’s environment

External sustainability practices (ESPs) involve especially suppliers to make the entire supply chain more sustainable.

Sustainability practices can be adopted differently, leading to different outcomes that can be:

- operational, e.g., quality, cost, flexibility, and delivery

- environmental, e.g., reduction of pollution, a decrease in waste of resources and energy, and a reduction of CO2 emissions

- social, e.g., labour conditions and living wage

- economic and financial (performance improvement)

An interesting aspect to consider is the fact that companies can also gain a differentiation advantage through eco-friendly products, satisfying the demand of today’s more conscious customers who expect to find sustainable offers on the shelves.

Therefore, implementing sustainable practices, both internally and externally, improves sustainability outcomes and lets companies respond to clients’ and stakeholders’ requirements and expectations.

To gain a competitive edge in the market, however, sustainability outcomes can’t exclude manufacturing issues, such as quality, lean production, and efficiency.

A wood product manufacturer should use sustainability practices strategically to support competitive advantage and create eco-friendly custom wood products that are also aesthetically beautiful, functional, and top quality.

Consumers won’t buy eco-friendly products that are not functional and appealing.

Today, in fact, wooden items are not just simple objects: people consider them decorative elements to display in their homes, and they must respond to their needs and requests.

.jpg?width=500&name=Th-legnavis-green-3(1).jpg) So, how do you recognize a real eco-friendly wood product manufacturer?

So, how do you recognize a real eco-friendly wood product manufacturer?

The following is the definition of sustainable business by Wikipedia:

A sustainable business, or a green business, is an enterprise that has minimal negative impact or potentially a positive effect on the global or local environment, community, society, or economy […] In general, business is described as green if it matches the following four criteria:

- it incorporates principles of sustainability into each of its business decisions

- it supplies environmentally friendly products or services that replaces demand for nongreen products and/or services

- it is greener than traditional competition

- it has made an enduring commitment to environmental principles in its business operations

Sustainability concerns the whole production process of the manufacturing company.

It refers to doing the entire business without negatively affecting the planet and society, from collection of the raw materials to production and distribution, finding a balance between profitability, environmental concern, and social commitment.

However, here are some aspects to evaluate about the wood product manufacturer you select to make a conscious choice.

It complies with the standards

Besides FSC and PEFC certifications (essential to ensure that products are manufactured with raw materials coming from responsibly managed forests), there are other regulations a wood maker should comply with:

EUTR 995 was introduced in 2013 to control operators and traders that place wooden products on the European market. Its aim is avoiding the circulation of illegally harvested timber, ensuring stronger monitoring of the supply chain.

The Lacey Act is very similar to EUTR 995 but is valid for trade in the United States.

REACH (EC 1907/2006) is a European Union regulation that aims to protect human health and the environment from potential risks caused by chemical substances.

It works to reduce the company’s carbon footprint

An eco-friendly manufacturer does its best to reduce greenhouse gas emissions. For example, producing wooden components where raw material is collected makes transportation logistics more sustainable.

In fact, shortening the process that raw materials go through to reach production helps reduce pollution caused by vehicle emissions, which contributes to safeguarding the environment.

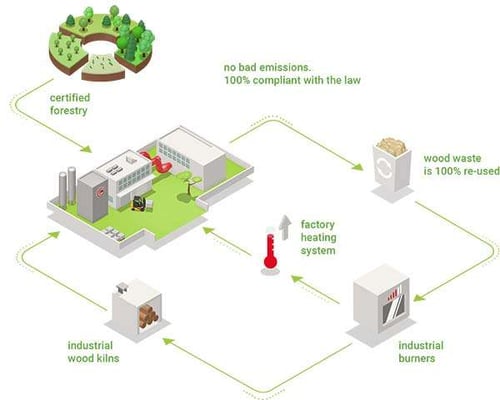

It adopts a circular economy model

How the wood product manufacturer manages and reuses resources is important to understand if it adopts an eco-friendly approach.

For example, if the wood maker produces a cutting board, a knife chop, or a bath brush, it could use discarded materials to create wooden blocks that are carefully stocked for future production of smaller items, such as wooden toothbrush handles or wooden cosmetic caps, significantly reducing waste.

It uses energy-efficient implants and monitor consumption

It uses energy-efficient implants and monitor consumption

A wood maker that really cares about the environment constantly monitors its energy consumption, periodically conducting specific audits to understand the whole picture of the company’s energy usage and increase its efficiency.

The Minelli Group has always focused on sustainability: in 1999, we were among the first to be certified by the FSC when it was not yet a standard. Today, we are also PEFC certified.

We recently underwent an EcoVadis Audit and received a highly positive rating in terms of environmental, labor & human rights, ethics, and sustainable procurement impact.

This demonstrates our sincere dedication to pursue a responsible manufacturing model that respects the environment as well as all ethical aspects of business.

If you are looking for a sustainable wood manufacturing company, do not hesitate to contact us!