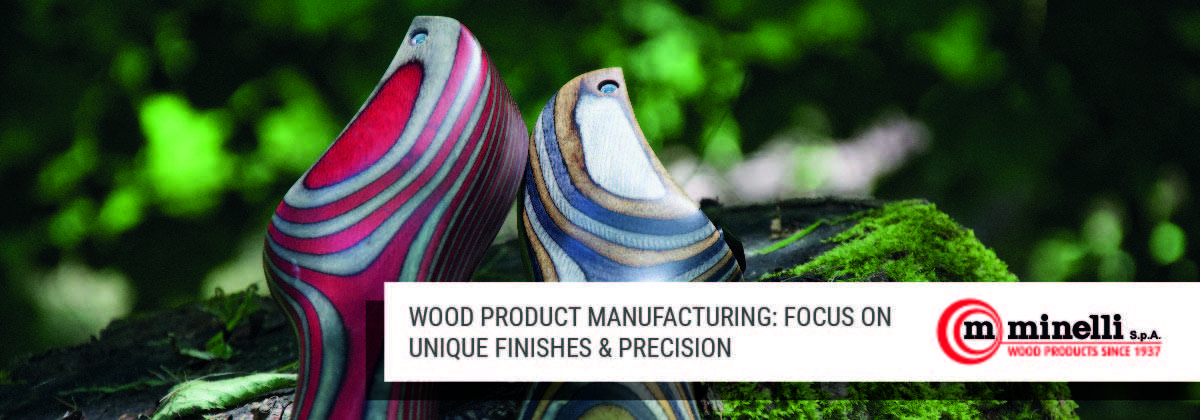

Hundreds of types of wood exist in nature, each with its own characteristics and peculiarities. Some are very precious and expensive, while others are poorer and cheaper, but each type can be enhanced and transformed thanks to the numerous finishes available in the market. Let’s talk about this topic in the following article.

Hundreds of types of wood exist in nature, each with its own characteristics and peculiarities. Some are very precious and expensive, while others are poorer and cheaper, but each type can be enhanced and transformed thanks to the numerous finishes available in the market. Let’s talk about this topic in the following article.

The importance of the finishing process in wood product manufacturing

When a client decides to include custom wood products in his catalogue, one of the most frequently asked questions is: What is the best finish for this type of wood? There isn’t a single right answer. The finish you choose depends on many factors, including the result you want to get, the design you are looking for, and the level of protection you desire. Even if there isn’t a wrong or right finish for a certain type of wood, however, some finishes work better in certain situations and for specific purposes. Generally, you decide to use a finish on your product for two main reasons:

- Protection, e.g., to make it more resistant to impact, water, humidity, and wear

- Appearance, e.g., to make it more glamourous, aesthetically beautiful, and distinctive

Different finish options offer varying levels of protection, covering, durability, renovation, and aesthetics. Some resins and paints are made to cover the natural colour of timber, while others improve its appearance or transform the look and feel of the product, making it soft to the touch, velvety, plastic-like, or shiny. The most important factor is for the surface to be prepared properly: it must be clean, smooth, and free from dirt, dust, and oils. Sanding, scraping, or planing operations are generally required to get a perfect base for the wood product manufacturing.

With that in mind, let’s have a look at the main options available and what differentiates them.

With that in mind, let’s have a look at the main options available and what differentiates them.

There are two different groups of finishes: surface finishes (e.g., shellac, lacquer, wax, and varnish) and penetrating ones (i.e., every type of oil):

- Surface finishes provide moderate protection, and the coating is quite durable, leaving the natural appearance of wood. The advantage is that they can be an effective base for other coatings.

- Penetrating finishes are very durable. They infiltrate wood’s pores and fibres, and they make wood look richer and more translucent.

What about sustainability?

Today, everyone should do something to reduce his carbon footprint. For this reason, we can consider a third group, which includes organic water-based lacquers.

These types of lacquers are created with ingredients derived from recycled materials and renewable sources (i.e., water and organic resin), with a very low content of VOC (volatile organic compound). The most important point to consider is that their production process has less of an impact on the environment compared with petroleum products, thanks to a significant reduction in CO2 emissions.

Using organic lacquers has many advantages:

Using organic lacquers has many advantages:

- Help reduce the use of oil

- Allow the reduction of carbon dioxide emissions during wood product manufacturing

- Are less dangerous for people and employees’ health

Water-based resins also guarantee exceptional technical performance, comparable to those of petroleum-based products in terms of hardness, chemical resistance, and industrial workability. They also respond to the qualitative standards demanded by the timber industry without damaging our planet.

The wood maker makes the difference

To determine which is the best finish for a given object, your supplier must carefully consider your needs to find the best solution. Selecting a manufacturing company that operates exclusively in the timber sector can be crucial. In fact, by managing different types of products (such as wood packaging, caps, brushes, stocks, toys, and hand tools), experts will be able to:

- treat wood properly, being thoroughly familiar with its specific characteristics and typical tolerances

- satisfy every customer request, even the most complicated, thanks to experience gained across different industries

You must also ensure that your supplier has an internal R&D department that works to create innovative materials, offer new product development, and solve possible problems arising during the process of wood product manufacturing.

You must also ensure that your supplier has an internal R&D department that works to create innovative materials, offer new product development, and solve possible problems arising during the process of wood product manufacturing.

This is what distinguishes Minelli S.pA: specialized experts work in specific sectors to develop top-quality wooden products, but they also communicate with the other teams. This process allows us to satisfy our customers’ requirements, from the design phase to the concrete creation of the product, putting our technologies and tools at their service. Collaboration with our clients is crucial. Thanks to the expertise and know-how of our teams, we can analyse each project with our clients and together decide the best way to achieve their goals. We want to help them improve and optimize their products even before production, suggest innovations and product development, always guaranteeing maximum precision and quality consistency, even for large lots of production parts. Moreover, we want to maintain our high-quality standards in preparing and painting wooden components, paying strict attention to our ecosystem and reducing atmospheric pollution. That’s why we use organic water-based lacquers in our production lines, always preserving the highest quality finishes. We can also guarantee a healthier working environment for our employees who use these lacquers, as they do not produce unpleasant chemical smells.

We always put our expertise and innovative technology at our clients’ disposal, doing our best to satisfy them. If you have a project in mind, please contact us: click here!