The goal of an experienced wood manufacturer is meeting even the most complicated and demanding clients’ needs, respecting deadlines, and guaranteeing cost-effectiveness.

The goal of an experienced wood manufacturer is meeting even the most complicated and demanding clients’ needs, respecting deadlines, and guaranteeing cost-effectiveness.

Sometimes this means creating complex shapes and designs and experimenting with new technologies, finishes, and tools to create successful objects that are aesthetically beautiful and functional too.

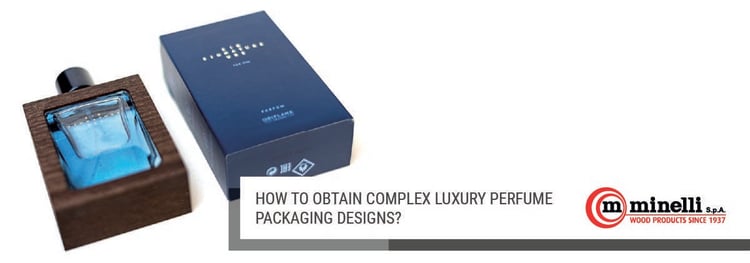

In this article, we discuss a case study involving the creation of a wooden frame for luxury perfume packaging that opened and closed without glue so that the customer could remove the scent and use the frame for photographs.

How to create luxury perfume packaging that satisfies clients’ needs

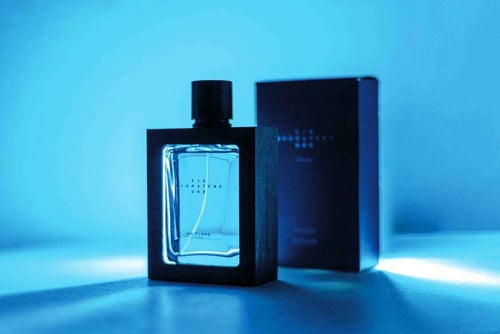

Offering something unique and innovative is the key to be competitive in today’s market and especially the luxury market. A fragrance is not just an object for many people; it is something that represents them and their personality with not only its scent but also its appearance.

Luxury perfume packaging is therefore crucial to attract customers’ attention and convince them to buy.

Consider also that distinctive and beautiful wooden packaging for perfume can be a real collector’s item and something people will want to display in their homes.

Perfume packaging can’t be underestimated when creating a new fragrance. Luxury brands and companies know that very well and always look for cutting-edge packaging solutions for their fragrances.

One of the most demanding projects completed by Minelli was creating innovative luxury perfume packaging that consisted of a square wooden frame that enclosed a glass bottle and could be opened and closed without glue.

The idea was that once the fragrance was finished customers could remove the glass bottle and use the wooden frame as an object of design and possibly for displaying photos.

What were the necessary steps for creating this wooden frame for perfume bottles?

The initial project included four pieces of wood joined by small nails, but this was not functional and convenient, as the glass perfume bottle could not be blocked safely, and the system wasn’t cost-effective.

Moreover, nails posed significant safety problems in manufacturing and consumer use.

How did Minelli solve this issue?

Doing trials, tests, prototypes, and experiments to find the solution to a problem is the only way to solve it. This often means failing, figuring out what the problem is, trying again, and finding the best way to meet the customer’s request.

Of course, it requires innovative tools, state-of-the-art machinery, and a team of experts willing to keep trying until the desired result is achieved.

A company accustomed to completing innovative and out-of-the-ordinary projects, which often no one else can do, will be able to leverage the experience and knowledge of its engineers and technicians to find the best solution.

In the case of the wooden frame for luxury packaging, we identified “press fit” to be the best solution. A press fit is an assembly in which one part is inserted tightly into a hole in another part. To incorporate this technology, we redesigned the product and eliminated all nails.

The modified design helped achieve the cost target and improved safety.

The client could then launch this unique and distinctive product that has achieved great success in the luxury perfume market.

Observing the market and creating innovative products is necessary to stay competitive. Besides being aesthetically beautiful and functional, the wooden frame is also very much appreciated because it is an eco-friendly solution for packaging.

Observing the market and creating innovative products is necessary to stay competitive. Besides being aesthetically beautiful and functional, the wooden frame is also very much appreciated because it is an eco-friendly solution for packaging.

Press fit technology lets us avoid the use of glue and nails to create a wooden object 100% sustainable. Moreover, once the fragrance is finished, the frame can be reused following the principle of a circular economy.

These characteristics made it very successful.

To create unconventional and custom-made wooden products, it is fundamental to select a manufacturer with deep experience in wood processing and recognized as an expert in the field even by its main competitors.

Moreover, the right supplier is ready to listen to your and your customers’ requirements, give advice, and try to solve any problems.

Since 1937, Minelli S.p.A. has ensured perfection in the quality and design of each product manufactured, and its experienced specialists serve customers in the best way possible following rigorous processes and environmental sustainability.

If you would like to offer unique and distinctive luxury perfume packaging, don’t hesitate to contact us! Our experts will be glad to evaluate your project and help shape your idea.