A modern manufacturer of perfume packaging needs technical expertise to produce precise, top-quality, and consistent products. Especially if you are looking for wooden items, when selecting your supplier, you should look at the manufacturing process it employs to understand if it will be able to create the objects your clients want.

How do you know if your manufacturer invests in technology? Read the following article to find out.

Production of perfume packaging: the role of technology

Creating wood packaging is complicated, as wood requires specific machinery to be managed properly, and its production process consists of many different phases with each one crucial for a perfect result:

- Codesign

- Prototyping

- Ordering

- Material preparation

- Production

- Finishing

- Quality control

- Delivery

If each of these phases is digitalized and automated, you will be able to guarantee maximum accuracy and precision for each single product of each production lot.

Let’s analyse the role of technology in each step of the production process of wooden perfume packaging.

Codesign

Codesign is the step when you talk with clients to understand their needs and determine if their idea is feasible with certain machines and a specific wood essence to get a perfect result. Each type of wood has different characteristics and tolerances that an expert wood maker must know and consider during the codesign phase.

The manufacturer should also be able to simulate even the most difficult drawing, as a multifaceted wood cap, using the latest CAD-CAM software without altering the original idea of the project.

Prototyping

Seeing and touching realistic prototypes of the final product is a great advantage to predict possible problems and determine if some modifications are required before production.

A competent wood manufacturer can provide them starting from the 3D model developed during the design phase thanks to the most innovative 3D printing techniques, additive technology, and fast prototyping.

Ordering

Tracking the status of the order h24 is essential to advise clients if any delays will occur and tell them precisely when their order will be sent guaranteeing a positive customer experience. This is only possible if the supplier has a dating platform and a fully automated and accurate production planning system.

In fact, only the latest generation production scheduling systems can automatically date the order and communicate it to commercials so that they can constantly update clients about shipping.

Material preparation

To create high-quality perfume packaging that protects the contents and avoids product leakage, it is essential to carefully prepare the raw material. The drying process is especially important to ensure the ideal moisture content of the wooden log before production.

The most advanced manufacturing companies have in-house drying chambers to perform the drying process internally rather than outsourcing to ensure the best quality and longevity of the final product.

The most advanced manufacturing companies have in-house drying chambers to perform the drying process internally rather than outsourcing to ensure the best quality and longevity of the final product.

Production

Multipurpose production equipment is most common but not ideal to manufacture very specific and particular types of products. A technology-advanced manufacturer develops a dedicated production line for each specific item to meet clients’ requirements and ensure accuracy, brief lead time, and higher volume.

The most advanced digital systems also help monitor production at each stage, which is necessary to estimate costs accurately, manage overall production lead time, and be able to react timely to any issue that might happen.

Finishing

The finishing step is important to produce the perfume packaging your clients want.

Automatic painting systems, advanced laser finishing, as well as anthropomorphic laser robots—which can adapt to every shape with radial movements and different engraving depths—are crucial to personalize each item according to clients’ requirements and create complex shapes and unique designs.

Quality control

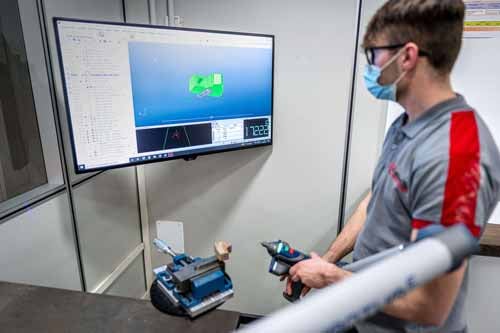

Some wood caps or packages have very complex designs, and precise measurements can be very difficult. If made manually, mistakes that compromise the product’s functionality are quite possible.

3D laser technology and sophisticated metrology software are necessary to guarantee accurate and 100% reliable measurements. This method consists of scanning the wooden item with a laser gun connected to metrology software that creates a three-dimensional representation of the item. Then the representation is compared with the original technical drawing to verify that nominal dimensions and tolerances are correct.

All types of wooden perfume packaging should be individually checked with automatic systems of infrared video cameras and tailor-made artificial intelligence algorithms to ensure products that meet all customer specifications and expectations.

All types of wooden perfume packaging should be individually checked with automatic systems of infrared video cameras and tailor-made artificial intelligence algorithms to ensure products that meet all customer specifications and expectations.

Digitalized quality control systems ensure the highest accuracy.

Delivery

Well-managed delivery guarantees that the product arrives on time and in perfect condition.

All items should be automatically packed according to customer specifications in safe and clean warehouses to guarantee they are carefully stored.

Logistics should also be digitalized and integrated to improve the supply chain process and make it agile for an excellent customer experience.

The Minelli Group is known all over the world for its digital systems, sophisticated software, and cutting-edge machines.

We employ only the latest generation of customized and made-for-purpose CNC machines that provide consistent dimensional and finishing results even at a very high production volume.

Thanks to our own Manufacturing Execution System (MES), our company is fully connected, and we have recently implemented new 3D metrology technology that lets us guarantee maximum precision for each production lot.

We have production plants in both Europe and the U.S., and we can provide customizable private stocking solutions to guarantee just in time delivery. It means we can manufacture your wooden components in advance and store them in secure and safe warehouses so that you can order from stock with virtually instantaneous delivery.

Moreover, our internal R&D department constantly observes the market to develop innovative finishing options according to market trends and customers’ preferences.

If you have a project in mind, don’t hesitate to contact us! Our experts will be glad to evaluate your project and help make it real.