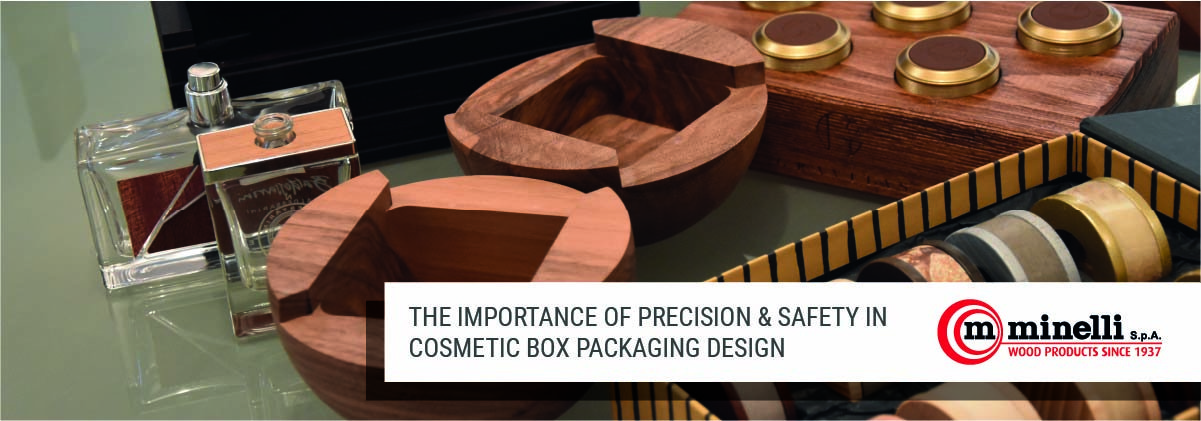

Proper cosmetic box packaging design is essential to get a functional, accurate, elegant, and precise object. Choosing the best manufacturer is therefore fundamental to satisfy each client’s needs.

Proper cosmetic box packaging design is essential to get a functional, accurate, elegant, and precise object. Choosing the best manufacturer is therefore fundamental to satisfy each client’s needs.

You need a producer that can assist you and your client during every step of the process, from the design phase to manufacturing to distribution, which will ensure a product that corresponds to your clients’ standards, delivered on time at a competitive price.

In this article, we discuss how the choice of the right supplier can make the difference to get a perfect product.

Looking for a unique cosmetic box packaging design? Here are our considerations

Packaging design doesn’t concern just the aesthetics of the package but also its precision and safety. Cosmetic packaging must be solid and resistant to guarantee the protection of the content inside, avoiding contamination and product leakage.

It is crucial to find a manufacturer with the right machines, tools, and expertise to manage wood properly and ensure perfect products without renouncing customization and glamorousness.

Clients, in fact, look for innovative designs, new styles, and unusual finishes.

If you can rely on an expert supplier that satisfies your requests and supports you during the entire process, you can create unique and amazing objects.

To get perfect wooden products, you need an expert and meticulous partner

The support of the wood maker can be a turning point in your project, as he can help you improve the cosmetic box packaging design from the beginning, before production, giving advice based on his experience.

A manufacturer with extensive experience in the timber sector knows market trends and can be a precious consultant to create a successful product.

It is important to be able to see a physical sample of the final bottle, box, cap, or container, to know if it corresponds to your client’s idea, and to predict and adjust possible problems and technical issues.

The prototype must be realistic. If it resembles the final product but doesn’t correspond 100%, you might run into serious difficulties when you start actual production, e.g., delays or unexpected costs.

The possibility of producing goods in small lots provides greater efficiency too. Being able to deliver half-processed products and then complete production depending on market trends and consumers’ preferences gives you a better chance of success.

Advanced technologies are required to create state-of-the-art wooden components

Wood is not easy to manage, and you need competencies and special machines to treat it properly. Unconventional shapes require the highest attention and deep quality control to ensure precision for each production lot.

That’s why small cylindrical and rounded shapes are so common; larger diameters, multifaceted caps, and any other geometrical shapes are feasible too, but the manufacturer must have the right machinery and tools to manage wood correctly guaranteeing a safe and precise component.

-compressed-1.jpg?width=500&name=banner-perfume-1(1)-compressed-1.jpg) Strict tolerances must be respected meticulously to create accurate and solid cosmetic packaging designs, avoiding discrepancies. If your supplier has the most advanced measurement technologies, he will be able to ensure maximum precision.

Strict tolerances must be respected meticulously to create accurate and solid cosmetic packaging designs, avoiding discrepancies. If your supplier has the most advanced measurement technologies, he will be able to ensure maximum precision.

Measurements that are made manually, i.e., using manual calipers, rulers, or goniometers, have a higher probability of error, as they depend on the ability of the operator, his competency, and concentration. The most advanced 3D laser technology and metrology software make the entire process automated, faster, and more accurate.

Besides automation and sophisticated software, however, you must ensure that your partner also performs manual quality control over production, which is essential for greater precision and consistency.

You should also offer customization options

Packaging must be functional, accurate, and safe, but it must be elegant and prestigious too. Personalized packaging is very popular today, and the market offers many finishing options, for example:

- oil, oil + wax, and oil + wax + polymer finishes

- classic paints

- water-based finishes

- embossing & engraving

- soft-touch finishes

- polymer coatings

A company with a decennial heritage can rely on relationships and collaboration with the world’s leading producers of wood finishing materials and offer all the options available in the market.

It is also necessary for your supplier to advise you about the best option to use in each specific case, as some finishes work better than others in certain situations and for specific purposes, depending on your clients’ needs.

A competent wood manufacturer can have access to a wide range of finishing options, he knows the differences among them and can create a product that can satisfy each client’s need.

Precision is crucial to guarantee a safe cosmetic box packaging design. Wooden components are designed to be combined with other materials and they must be suitable for the specific object. If the cap doesn’t fit perfectly on cosmetic container, for example, there can be problems with product leakage or contamination.

The Minelli Group is known around the world for its high standards, the quality and precision of its products, and the wide range of finishes it can offer.

If you have a project in mind, don’t hesitate to contact us! Our experts are at your disposal.