Safety is essential for wooden cosmetic containers, both for functional and hygienic reasons. Bottles and caps must be aesthetically beautiful to convince people to buy, but they must also protect the content and prevent product leakage.

Safety is essential for wooden cosmetic containers, both for functional and hygienic reasons. Bottles and caps must be aesthetically beautiful to convince people to buy, but they must also protect the content and prevent product leakage.

Many people believe that wood packaging is less safe than plastic, but this is not true if the raw material is properly manufactured.

Let’s discuss this topic in the following article.

How to ensure the wooden cosmetic containers you offer are safe

Wooden cosmetic containers have two main functions:

- to attract buyers’ attention and reflect brands’ identity

- to ensure the content is protected and properly stored

Today, we deal with the second point, which concerns safety.

What does safety mean?

Safety can involve functionality and hygiene.

Safety & functionality

Cosmetics are generally liquid, so they are more subject to leakage while at the store and in consumers’ homes. They could also deteriorate if they come in contact with oxygen or be contaminated by external elements.

It means that the wooden cosmetic cap must fit perfectly on bottles or boxes to ensure quality and durability of the content inside and avoid negative effects on brands’ reputation and credibility.

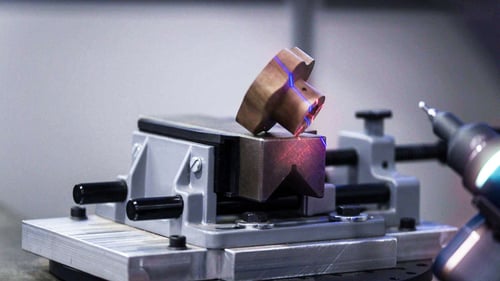

A high-precision mechanical approach—with the right tools and machinery—should be applied in wood machining to achieve superior results.

Wood is very difficult to manufacture, as each essence has different structural limits and precise tolerances that must be considered to create state-of-the-art products.

Wood is very difficult to manufacture, as each essence has different structural limits and precise tolerances that must be considered to create state-of-the-art products.

Each type of wood also has specific characteristics in terms of hardness, flexibility, grain size, and machinability that can’t be ignored.

The expertise of the manufacturer is therefore essential. It must be specialized in managing wood to know the precise tolerances to respect and create perfect wooden components.

Sometimes the desired shape might be hard to replicate. The supplier should be able to simulate even the most difficult drawing without disturbing the concept and the general feeling of the original project, always guaranteeing maximum qualitative standards and precision.

Wooden components often need to be combined with other materials—such as glass or plastic containers—and they must be suitable for the specific object.

Quality must also be consistent

If you order millions of wooden cosmetic containers and caps, the same precision and safety have to be guaranteed for each production lot.

This requires advanced technologies, groundbreaking measurement technology software, and innovative tools. If the company invests a lot in the newest systems and all the processes are based on automation, interconnectivity, machine learning, and real-time data, it means that it can respond to even the most complex challenges.

You must also ensure that all cosmetic containers are individually checked for:

You must also ensure that all cosmetic containers are individually checked for:

- dimensional and functional aspect (size and shape)

- milling accuracy (missing parts, dents, splinters, breakage)

- morphological defects (open knots, heavy discoloration)

Quality control is one of the most important factors to evaluate when choosing your ideal partner.

Another aspect to consider is the production process

Most wood manufacturers use multipurpose production equipment to create wooden cosmetic containers among other items. However, these components would need a dedicated production line to ensure:

- accuracy

- cost-effectiveness

- high production capacity

- short lead time

The production process of cosmetic packaging requires specific technologies and tools to provide consistent dimensional and finishing results even at a very high production volume.

Safety & hygiene

Cosmetics are often placed near the sink in the bathroom, which is a very humid environment. This could cause the development of bacteria and molds, as they require moisture to grow.

The proliferation of molds can be a major problem, as these microorganisms can cause allergic reactions in sensitive people, including sneezing, runny nose, red eyes, and skin rash.

The proliferation of molds can be a major problem, as these microorganisms can cause allergic reactions in sensitive people, including sneezing, runny nose, red eyes, and skin rash.

Safety also means avoiding these situations, which are risky for people’s health.

If treated correctly, wood is less likely to develop mold. Your supplier must be able to treat wood with special finishes that make it water repellent and avoid the growth of bacteria and fungus.

If a product is water repellent, it means that it is hydrophobic and repels water on contact. These types of finishes make wooden products safer and more hygienic than plastic ones.

To ensure a perfect application of finishes, it is also essential that the raw material is carefully prepared.

The drying process is especially important to guarantee the ideal moisture content to get a clean milling process, higher dimensional stability, and less probability of breakage.

You should verify that the supplier you select has in-house proper drying chambers. Each chamber should allow the possibility of adjusting levels of heating, spraying, and dehumidification according to the starting moisture content and type of wood used.

By ensuring such controls, you can obtain objects ready to be treated and customized according to your clients’ requirements.

Very often the problem involving cosmetic packaging producers is finding a partner that knows perfectly how to process wood and has the right machinery to manage it. Modern and innovative tools as well as meticulous processes of quality control are essential to create custom-made, top-quality, and precise wooden cosmetic containers.

Minelli S.p.A. has been managing wood for more than 80 years and can guarantee safe, durable, customized, and sustainable wooden products.

Do not hesitate to contact us!